The joys of owning 60+ year-old electronic photographic equipment, i.e. Ascor Sun Light strobes.

Equals…continuous maintenance or stockpiling of old equipment for parts or direct replacements.

You ask, why bother using these out dated, bulky, heavy and dangerous strobes. Well, they are the most powerful light source out there, yielding up to 45,000 watt-seconds in a single flash. This gives me the ability to stop action and movement while shooting wet plate collodion images.

Two carts holding 20 Ascor Condensers (capacitors), equivalent to 16,000 watt-seconds of potential strobe power. Each Condenser weighs in at 65 lbs. each.

The film speed/ISO of the collodion emulsion is about “0” or slower in the the film speed index. And that does not take in to count the bellows factor if I shoot 1:1 or larger ratio on a Ultra Large Format camera. I think the slowest adjusted film speed index I’ve shot is about, minus ISO 6. That is about 11 stops slower than ISO 100.

Besides that, I love HIGH VOLTAGE and enough power to light up buildings from a mile away.

So I’m always testing and checking wires for signs of cracking and charring. I hate surprises when you’re just starting or in a middle of a shoot and your strobes just decide to quit, and you smell that distinct odor of burning electrical components. Sometimes, unpredictable is a word to describe these strobes, but for the most part, they are great.

4000 VAC takes a toll on 60 year-old wires.

Did I mention what 4000 VAC will do to you? Put it this way, take the biggest screw driver you can find. You know, one of those that has a 3/8” dia. shaft and is about 24 inches long. Short the two terminals of a 50lbs 4000V capacitor with it and see what happens. If you live, you will have a shorter screw driver, a face full of molten metal and third degree burns.

Respect HIGH VOLTAGE…it will KILL YOU!

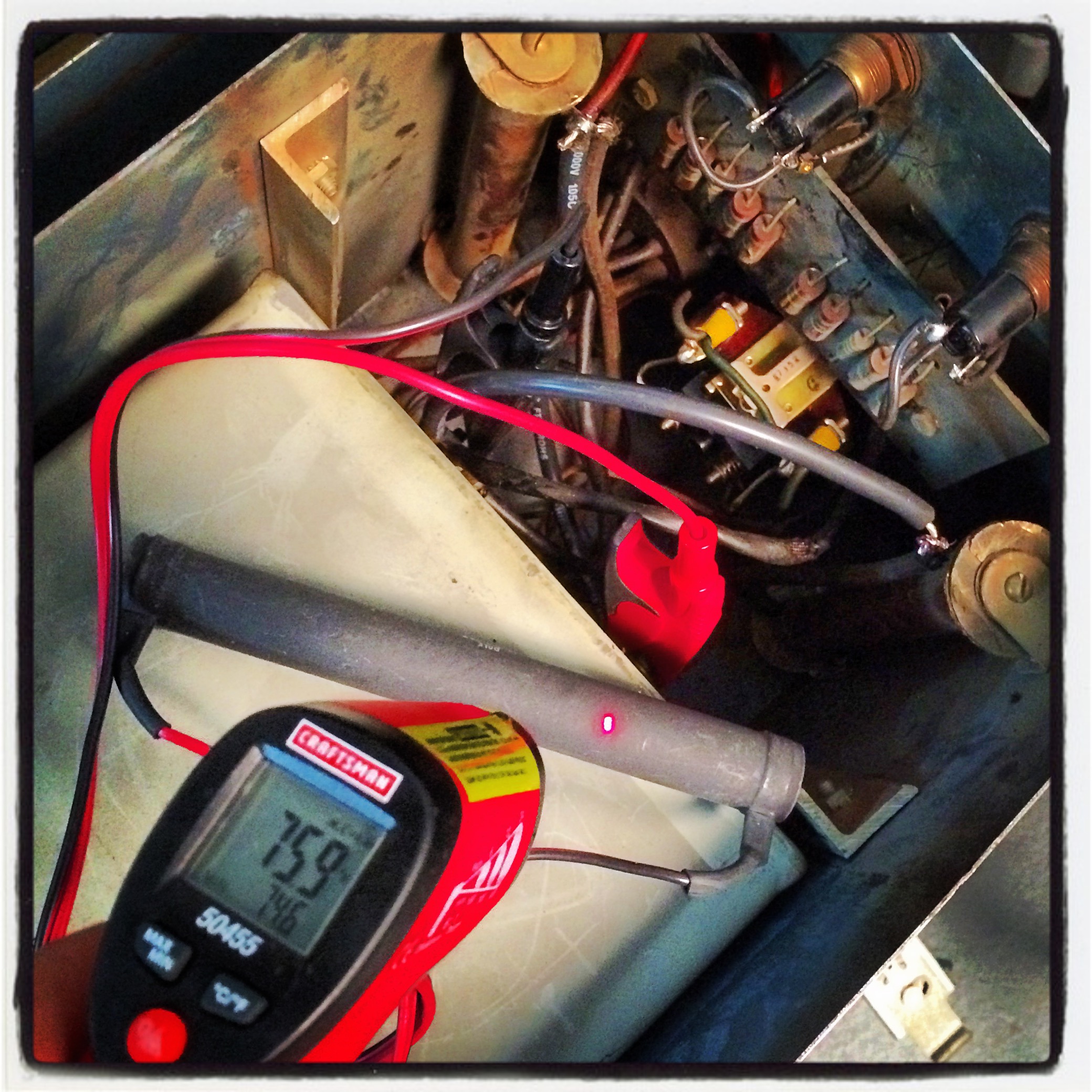

Monitoring resistor temperature during capacitor discharge.

So before doing any repairs or even putting my hands in to the box, I discharge the capacitor with a large 8” ceramic resistor. I monitor the temperature to gauge the discharge. Because using a multi-meter to check the voltage will do wonders to your meter. You only do that once, and yes I’ve accidentally have done that, I ended up with a $250 Fluke multi-meter rattle.

So to nights repair was a short in one of the molded connectors. Solution, moving the capacitor to another enclosure. Some times the only solution with old equipment, with damage to a proprietary components, is to just find another one.

A little bit of folk lore about the Ascor Sun Lights.

“when you purchase a set of Ascor strobes, you also get a broom stick. that is to pry your assistant off your stack of condensers after being electrocuted”